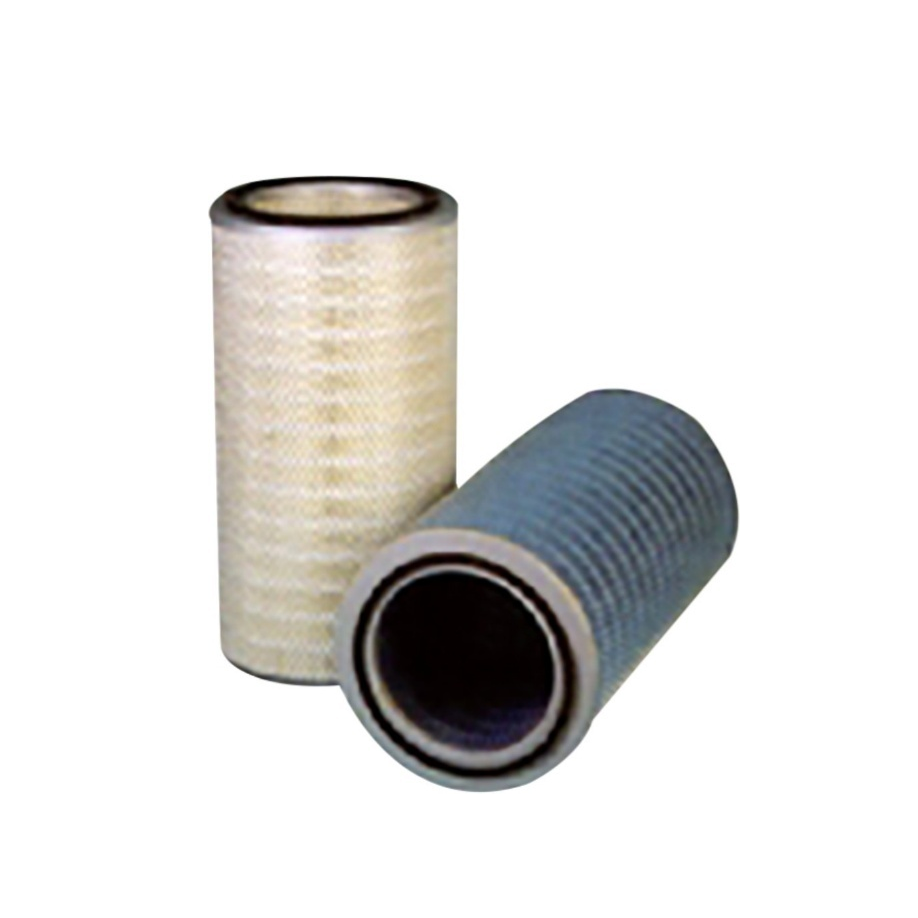

In the realm of industrial filtration, the pleated high-efficiency filter cartridge has emerged as a cornerstone technology due to its superior performance and versatility. These filter cartridges are designed to meet the stringent demands of various applications, ensuring high levels of filtration efficiency while minimizing pressure loss and operational costs.

Pleated Design: Maximizing Filtration Area

One of the most notable characteristics of the pleated high-efficiency filter cartridge is its pleated design. This design significantly increases the filtration area compared to traditional flat filters. The pleats create a more extensive surface for capturing contaminants, thereby enhancing the filter's capacity and longevity. This feature is crucial in applications where high volumes of air or liquid need to be filtered continuously, such as in HVAC systems, pharmaceutical manufacturing, and food processing.

Key Benefit: The large filtration area provided by the pleated design not only improves filtration efficiency but also extends the filter's lifespan, reducing the frequency of replacements and associated costs.

High Efficiency and Low Pressure Loss

Pleated high-efficiency filter cartridges are renowned for their ability to achieve high filtration efficiency while maintaining low pressure loss. The high-efficiency media used in these cartridges is capable of capturing particles as small as 0.3 microns with remarkable precision. This ensures that contaminants are effectively removed from the airflow or liquid stream, safeguarding the downstream equipment and processes.

Simultaneously, the pleated design and optimized media structure contribute to low pressure loss, which is essential for energy efficiency. The reduced pressure drop minimizes the energy required to push air or liquid through the filter, significantly lowering operational costs.

Key Benefit: High efficiency combined with low pressure loss makes pleated high-efficiency filter cartridges an ideal choice for energy-conscious applications, contributing to overall sustainability.

Convenient Installation and Maintenance

Another significant advantage of pleated high-efficiency filter cartridges is their ease of installation and maintenance. These cartridges are designed for quick and easy installation, often requiring no special tools or extensive training. This makes them highly suitable for applications where downtime needs to be minimized and operational continuity is crucial.

Furthermore, many pleated high-efficiency filter cartridges come equipped with a reverse jet cleaning device. This innovative feature allows for automatic cleaning of all filters in sequence while the system is still operational. By periodically removing accumulated contaminants, the reverse jet cleaning device helps maintain the filter's performance and extends its service life.

Key Benefit: Convenient installation and maintenance, coupled with the reverse jet cleaning device, ensure minimal downtime and maximize operational efficiency.

Technical Specifications and Materials

Pleated high-efficiency filter cartridges are available in a range of sizes and specifications to cater to diverse applications. The media used in these cartridges can be made from various materials, including polyester, polypropylene, glass fiber, and PTFE, among others. The choice of media depends on the specific requirements of the application, such as the type of contaminants, temperature range, and chemical compatibility.

Additionally, these filter cartridges often incorporate a metal or plastic housing to provide structural support and protect the media from damage. The housing material is also selected based on the application's needs, ensuring durability and compatibility with the operating environment.

Applications

The versatility of pleated high-efficiency filter cartridges makes them suitable for a wide range of applications. Some of the most common include:

HVAC Systems: In commercial and industrial buildings, these filters help maintain indoor air quality by removing particles, allergens, and pollutants.

Pharmaceutical Manufacturing: In cleanrooms and sterile environments, pleated high-efficiency filters ensure that contaminants do not compromise the integrity of the products being manufactured.

Food Processing: These filters protect food from contamination, maintaining hygiene and safety standards throughout the production process.

Electronics Manufacturing: In sensitive environments where dust particles can damage electronic components, pleated high-efficiency filters provide critical protection.

Automotive Industry: They are used in paint booths to ensure a flawless finish on automotive parts and vehicles.

Pleated high-efficiency filter cartridges offer a combination of advanced technical characteristics that make them indispensable in various industrial applications. Their pleated design provides a large filtration area, ensuring high efficiency and longevity. The optimized media structure and pleated design contribute to low pressure loss, significantly saving energy. Furthermore, the convenience of installation and maintenance, coupled with the reverse jet cleaning device, ensures minimal downtime and maximizes operational efficiency.

In conclusion, HEALU pleated high-efficiency filter cartridges are a robust and versatile solution for achieving high filtration performance in diverse industrial settings. Their technical characteristics and wide range of applications make them an essential component in maintaining the cleanliness, safety, and efficiency of modern industrial processes.