Fire safety measures are of paramount importance in every setting, and the functionality of fire extinguisher equipment is crucial for ensuring effective fire suppression. One significant component in a fire extinguisher is the bourdon tube gauge, specifically the 304 hexagon fire extinguisher bourdon tube gauge. Today, Safestar will take a closer look at the intricate manufacturing process behind this vital component.

I. Understanding the Purpose of the Bourdon Tube Gauge:

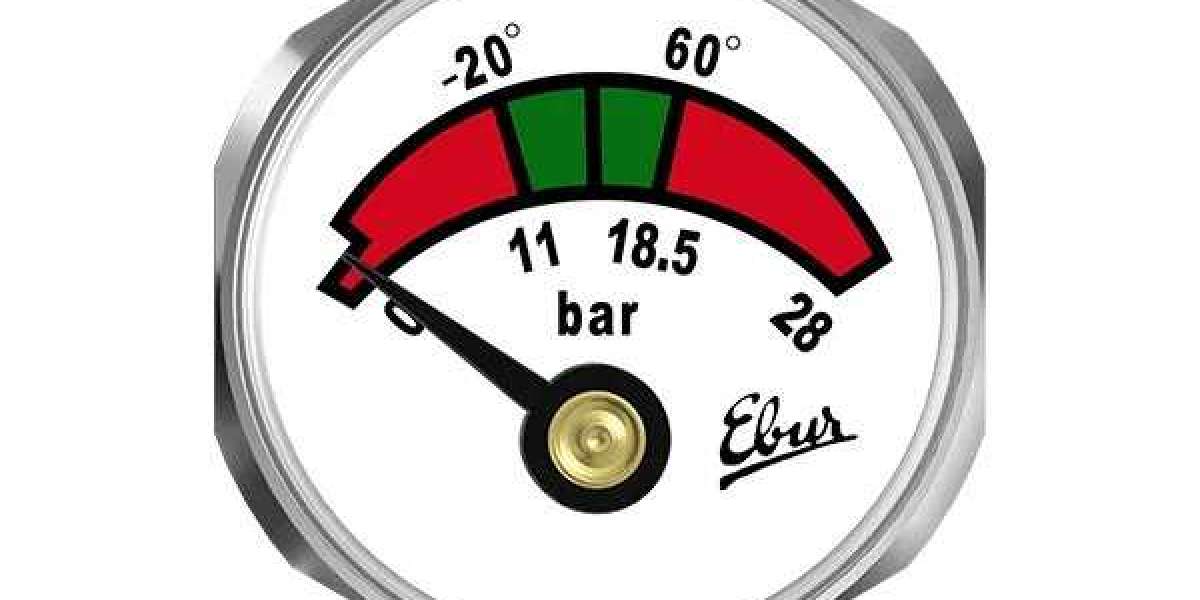

Before delving into the manufacturing process, it is essential to understand the role of the bourdon tube gauge in a fire extinguisher. The gauge is responsible for measuring and displaying the pressure level within the fire extinguisher cylinder. It provides users with a visual indication of whether the extinguisher is ready for use.

II. Material Selection and Preparation:

The first step in manufacturing a 304 hexagon fire extinguisher bourdon tube gauge is selecting the appropriate materials. The bourdon tube is made from high-quality stainless steel, specifically 304-grade stainless steel. This material is known for its excellent resistance to corrosion, high temperatures, and pressure, making it ideal for a fire extinguisher application.

Once the stainless steel has been chosen, it undergoes a thorough cleaning process to remove any impurities or contaminants. This ensures the final product meets the industry's high-quality standards.

III. Tube Formation:

To create the bourdon tube, the chosen stainless steel material is formed into a desired shape. The tube is typically made in a hexagonal shape, which allows for efficient transmission of pressure changes to the gauge indicator. This shape also enhances the overall structural integrity of the tube.

The metal is carefully cut and shaped using precision tools, ensuring the perfect dimensions and angles. Extreme attention to detail is required during this stage to ensure the tube's accuracy and functionality.

IV. Calibration and Testing:

Once the bourdon tube is formed, it undergoes calibration to ensure accurate pressure measurement. This step involves subjecting the tube to controlled pressure conditions and comparing the gauge reading to a known standard. If any deviations or inaccuracies are found, adjustments are made to achieve the desired calibration.

Following the calibration process, the bourdon tube gauge undergoes thorough testing to ensure its reliability and longevity. These tests involve subjecting the gauge to extreme pressures, vibrations, and temperature variations to simulate real-world conditions. The gauge must withstand these conditions without any failures or inaccuracies.

V. Surface Treatment and Final Assembly:

To enhance the bourdon tube gauge's corrosion resistance and overall durability, a surface treatment is applied. This treatment may include passivation, anodizing, or powder coating, depending on the manufacturer's specifications. These processes provide a protective layer, ensuring the gauge can withstand harsh environmental conditions.

Once the surface treatment is completed, the final assembly of the bourdon tube gauge takes place. This involves attaching the gauge indicator, ensuring proper alignment and secure attachment. Finally, the gauge is thoroughly inspected to confirm its functionality and appearance.

Conclusion:

The manufacturing process behind a 304 hexagon fire extinguisher bourdon tube gauge is complex and precision-driven. Every step, from material selection to testing and final assembly, is carried out with meticulous attention to detail to ensure the gauge's functionality, accuracy, and longevity.

Understanding the intricate manufacturing process behind this vital fire safety component highlights the dedication and expertise required to produce reliable and high-quality fire extinguishing equipment. Ultimately, these efforts contribute to the safety of individuals and properties in the event of a fire emergency.