Injection molding is a cornerstone of modern manufacturing, offering unparalleled efficiency and precision in the production of complex plastic components. As industries evolve, the demand for high-quality, cost-effective solutions has never been greater. In this context, Changhong Precision stands out as a leader in injection molding manufacturing processes, leveraging advanced technologies and innovative practices to meet the diverse needs of its clients.

Understanding Injection Molding Manufacturing Processes

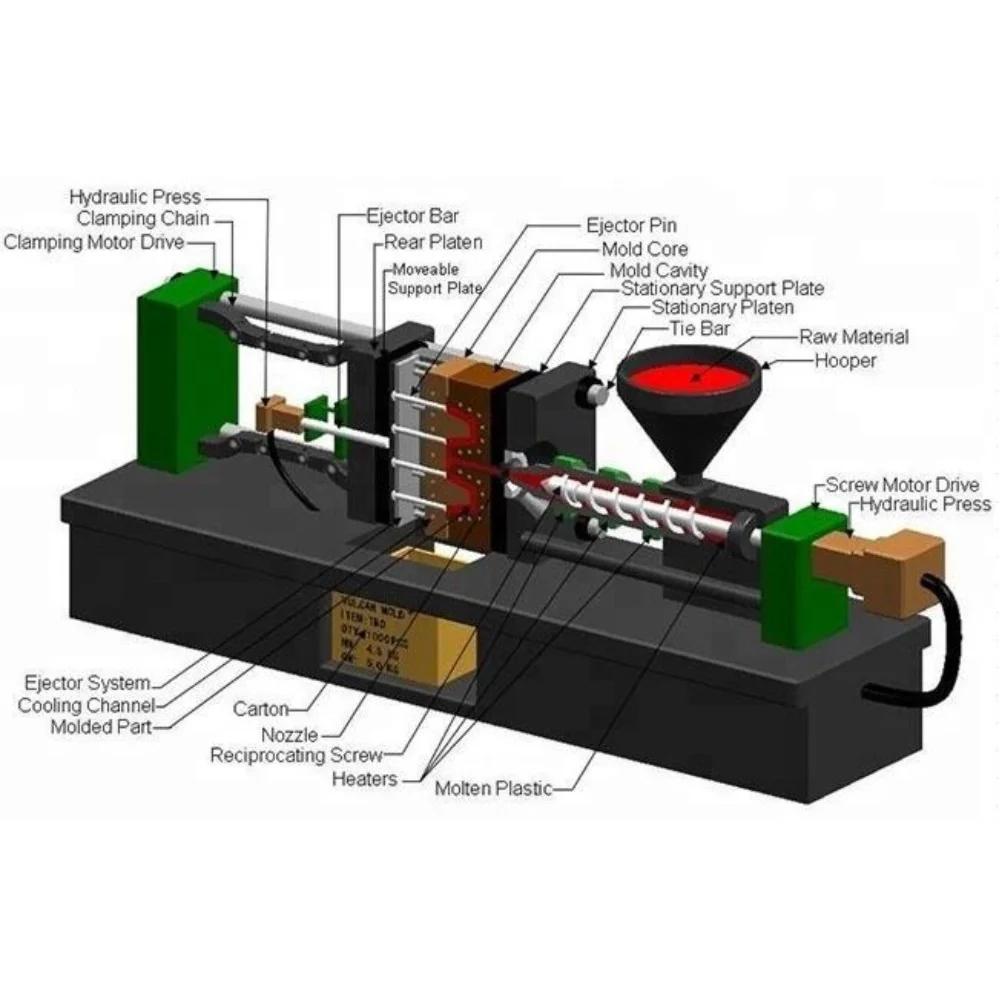

Injection molding is a manufacturing process that involves injecting molten material into a mold to create parts with intricate designs and specifications. This method is particularly favored for its ability to produce large volumes of identical parts with high precision. The process can be broken down into several key stages:

Material Selection: The choice of material is critical in injection molding. Common materials include thermoplastics, thermosetting plastics, and elastomers. Each material has unique properties that influence the final product's strength, flexibility, and durability

Mold Design: A well-designed mold is essential for successful injection molding. It must accommodate the thermal expansion of the material and allow for easy ejection of the finished part. Advanced CAD software is often used to create intricate mold designs that maximize efficiency and minimize waste.

Injection Process: The core of injection molding involves heating the selected material until it becomes molten and then injecting it into the mold under high pressure. This stage requires precise control of temperature and pressure to ensure uniform filling and minimize defects.

Cooling and Ejection: Once the material has filled the mold, it must be cooled to solidify. The cooling time can significantly affect production speed and part quality. After cooling, the mold opens, and the finished part is ejected.

Post-Processing: Depending on the application, additional processes such as trimming, painting, or assembly may be required to achieve the final product specifications.

Changhong Precision has established itself as a frontrunner in the injection molding industry by focusing on quality, innovation, and customer satisfaction. Here are several ways in which Changhong Precision excels in injection molding manufacturing processes:

Advanced Technology Integration

Changhong Precision employs state-of-the-art machinery and automation technologies to enhance production efficiency. By integrating Industry 4.0 principles, the company utilizes IoT devices and data analytics to monitor production processes in real-time. This not only optimizes machine performance but also reduces downtime and waste, leading to a more sustainable manufacturing process.

Customization and Flexibility

One of the key advantages of working with Changhong Precision is its ability to offer customized solutions tailored to specific client needs. The company collaborates closely with clients during the design phase to ensure that the final product meets all functional and aesthetic requirements. This flexibility is particularly beneficial in industries such as automotive, electronics, and consumer goods, where design specifications can vary significantly.

Quality Assurance

Quality control is paramount in injection molding, and Changhong Precision employs rigorous testing protocols to ensure that every part meets the highest standards. The company utilizes advanced inspection technologies, including 3D scanning and automated vision systems, to detect defects and ensure dimensional accuracy. This commitment to quality not only enhances customer satisfaction but also reduces the risk of costly recalls and rework.

Sustainability Initiatives

As the manufacturing industry faces increasing pressure to adopt sustainable practices, Changhong Precision is at the forefront of this movement. The company has implemented eco-friendly practices, such as using recycled materials and optimizing energy consumption in its facilities. By prioritizing sustainability, Changhong Precision not only meets regulatory requirements but also appeals to environmentally conscious consumers.

Conclusion

Injection molding manufacturing processes are integral to the production of high-quality plastic components across various industries. Changhong Precision exemplifies excellence in this field through its commitment to innovation, customization, quality assurance, and sustainability. As the demand for efficient and precise manufacturing continues to grow, companies like Changhong Precision will play a crucial role in shaping the future of the industry. By embracing advanced technologies and sustainable practices, they are not only meeting current market demands but also paving the way for a more efficient and responsible manufacturing landscape.

In conclusion, understanding the intricacies of injection molding and recognizing the contributions of industry leaders like Changhong Precision is essential for businesses looking to thrive in a competitive market.