In the textile industry, ensuring the durability and quality of fabrics is paramount. One critical aspect of this assessment is the resistance of fabrics to pilling, a condition where small fibers or yarn loops protrude from the surface, often caused by friction or wear. To accurately measure this resistance, the drum pilling tester has become an indispensable tool.

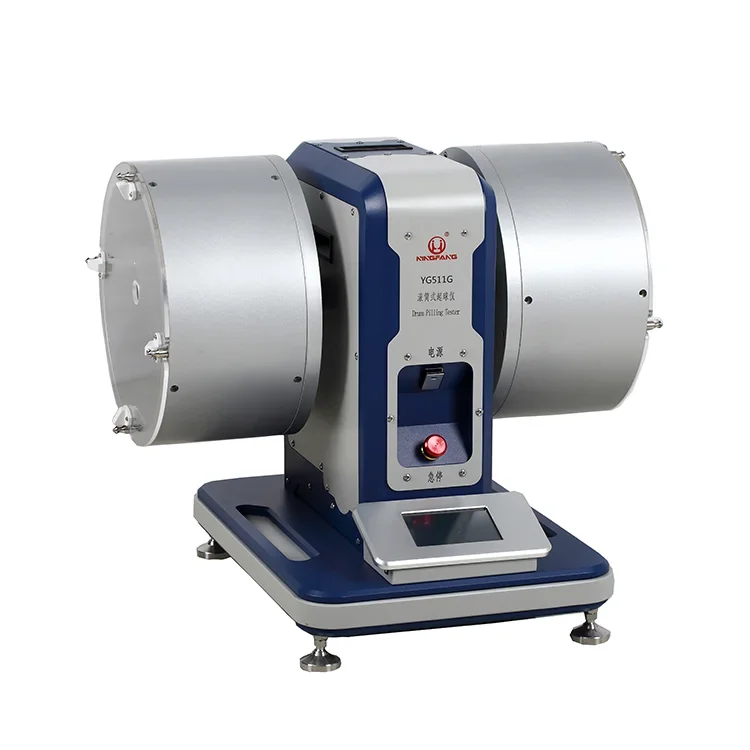

Key Features of Ningbo Textile Instrument Factory's Drum Pilling Tester

Advanced Testing Mechanism

Ningbo Textile Instrument Factory's drum pilling tester is equipped with a state-of-the-art testing mechanism that simulates real-world wear conditions. The drum rotates at precise speeds and durations, ensuring consistent and reliable test results. This advanced mechanism is designed to cater to various fabric types and thicknesses, making it a versatile tool for quality control in textile manufacturing.

User-Friendly Interface

Ease of use is a top priority for Ningbo Textile Instrument Factory. The drum pilling tester features an intuitive control panel and digital display, allowing operators to set parameters such as test duration, drum speed, and fabric specimen size with minimal effort. This user-friendly interface ensures that even novice operators can perform tests accurately and efficiently.

High-Precision Results

Accuracy is crucial in textile testing. Ningbo Textile Instrument Factory's drum pilling tester is engineered to deliver high-precision results, thanks to its precision-engineered components and advanced sensors. This ensures that fabric manufacturers can make informed decisions based on reliable test data, ultimately leading to improved product quality and customer satisfaction.

Durable Construction

Built to last, Ningbo Textile Instrument Factory's drum pilling tester is constructed from high-quality materials that can withstand the rigors of daily use. The robust frame and precision-ground drum ensure long-term durability and minimal maintenance requirements, making it a cost-effective investment for textile testing laboratories.

Operation Process

Preparation

1. Select Fabric Specimen: Choose a fabric specimen that represents the type of fabric being tested. Ensure the specimen is clean, free of defects, and cut to the specified size.

2. Set Parameters: Using the control panel, set the desired test parameters such as drum speed, test duration, and number of cycles.

3. Mount Specimen: Securely mount the fabric specimen onto the tester's drum, ensuring that it is properly aligned and tensioned.

Testing

1. Initiate Test: Press the start button to begin the test. The drum will rotate at the set speed, simulating wear and tear on the fabric specimen.

2. Monitor Progress: Observe the test in progress, ensuring that the drum operates smoothly and the fabric specimen remains securely mounted.

3. End Test: When the test duration is reached, the tester will automatically stop. Carefully remove the fabric specimen from the drum.

Evaluation

1. Inspect Fabric: Examine the fabric specimen for signs of pilling. Note the location, size, and density of pills.

2. Record Results: Document the test results, including any observations and measurements. Compare these results to industry standards or previous tests to assess fabric durability.

Precautions

1. Safety First

Always follow the manufacturer's safety instructions when operating the drum pilling tester. Wear appropriate protective gear, such as gloves and safety glasses, to minimize the risk of injury.

2. Regular Maintenance

Regular maintenance is essential for the long-term performance of the drum pilling tester. Clean the drum and other components after each use to remove fabric residue and debris. Inspect the tester for signs of wear or damage, and replace worn parts as needed.

3. Calibration

Ensure that the drum pilling tester is regularly calibrated to maintain accuracy. Calibration should be performed by a qualified technician using certified standards.

4. Proper Handling

Handle the fabric specimen with care to avoid damaging it before or during the test. Improper handling can affect the test results and provide misleading information about fabric durability.

Conclusion

The drum pilling tester is a vital tool for assessing fabric durability and resistance to pilling. Ningbo Textile Instrument Factory offers a high-quality drum pilling tester that combines advanced testing mechanisms, user-friendly interfaces, high-precision results, and durable construction. By following the operation process and precautions outlined in this article, textile manufacturers can ensure accurate and reliable test results, ultimately leading to improved product quality and customer satisfaction.

https://www.nbfyti.com/drum-pilling-tester-operation-process-and-precautions.html