In the realm of electrical engineering, contactors play a crucial role in the control of electrical circuits. Among the various types of contactors, the vacuum contactor stands out due to its unique operational characteristics and advantages. This blog post will delve into the working principle of a https://www.acvacuumcontactor.com/1-14kv-250A-Vacuum-Contactor.html, exploring its construction, operation, advantages, and applications.

What is a Vacuum Contactor?

A vacuum contactor is an electromechanical device used to switch electrical circuits on and off. Unlike traditional contactors that rely on air or oil for insulation, vacuum contactors utilize a vacuum environment to achieve superior performance. The absence of air eliminates the risk of arcing, making vacuum contactors highly reliable and efficient.

Key Components of a Vacuum Contactor

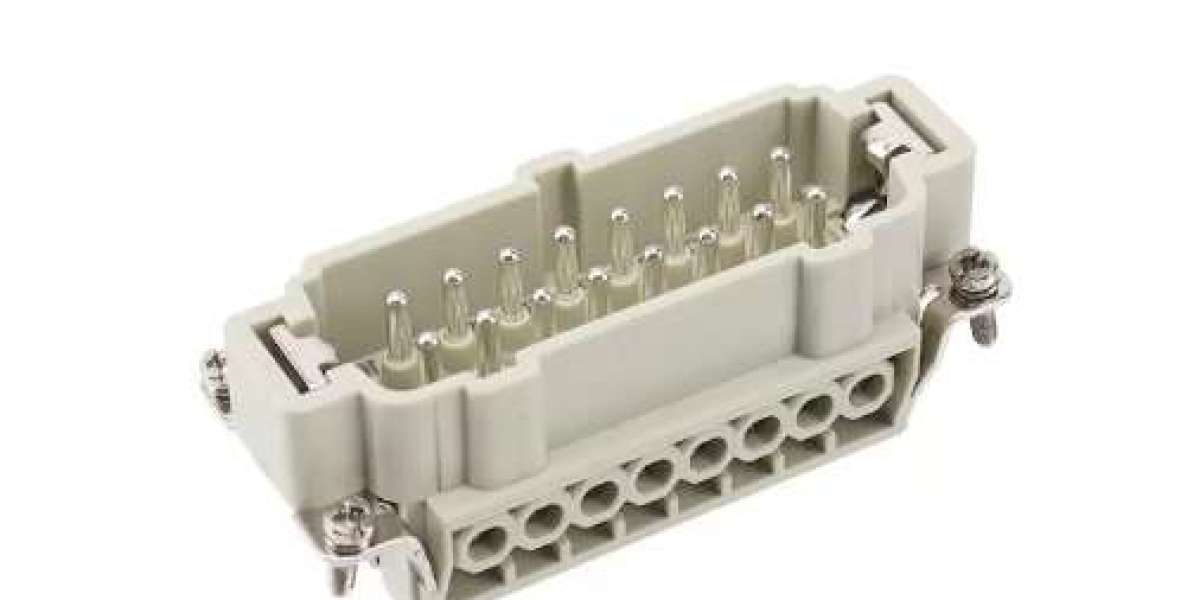

To understand how a vacuum contactor works, it's essential to familiarize ourselves with its key components:

Contacts: The primary function of the contacts is to establish or interrupt the electrical circuit. In a vacuum contactor, these contacts are enclosed within a sealed chamber that is evacuated of air.

Electromagnet: The electromagnet generates a magnetic field when current flows through it, allowing the contacts to close or open.

Operating Mechanism: This mechanism translates the movement of the electromagnet into the opening and closing of the contacts.

Sealed Chamber: The vacuum chamber is the heart of the vacuum contactor. It contains the contacts and is designed to maintain a vacuum, preventing arcing during operation.

Insulation: The vacuum itself serves as an insulator, allowing the contactor to operate at higher voltages without the risk of breakdown.

![]()

Working Principle of a 1.14kV 250A Vacuum Contactor

The working principle of a vacuum contactor can be broken down into several stages:

1. Initial State

In the initial state, the contacts of the vacuum contactor are open, and no current flows through the circuit. The electromagnet is de-energized, and the contacts remain separated due to a spring mechanism that holds them apart.

2. Energizing the Electromagnet

When a control signal is applied to the vacuum contactor, the electromagnet is energized. This generates a magnetic field that attracts the movable contact towards the fixed contact.

3. Closing the Contacts

As the movable contact approaches the fixed contact, the contacts close, establishing an electrical connection. The vacuum environment within the sealed chamber prevents any arcing from occurring at the moment of contact closure, ensuring a smooth transition.

4. Current Flow

Once the contacts are closed, current flows through the circuit. The vacuum contactor can handle up to 250A at a voltage of 1.14kV, making it suitable for various industrial applications.

5. De-energizing the Electromagnet

When the control signal is removed, the electromagnet is de-energized. The magnetic field collapses, and the spring mechanism forces the movable contact away from the fixed contact, opening the circuit.

6. Arc Quenching

As the contacts separate, the vacuum environment plays a critical role in quenching any potential arc that may form. The rapid movement of the contacts creates a high rate of change in current, which, combined with the vacuum, extinguishes the arc almost instantaneously.

Advantages of the 1.14kV 250A Vacuum Contactor

Vacuum contactors offer several advantages over traditional contactors:

1. Reduced Arcing

The vacuum environment effectively eliminates arcing during contact closure and separation, leading to longer contact life and reduced maintenance.

2. Compact Design

Vacuum contactors are generally more compact than their air-insulated counterparts, making them suitable for applications where space is limited.

3. High Insulation Resistance

The vacuum provides excellent insulation resistance, allowing vacuum contactors to operate at higher voltages without the risk of breakdown.

4. Fast Operation

The design of vacuum contactors enables rapid opening and closing of contacts, making them ideal for applications requiring quick response times.

5. Low Noise Levels

Vacuum contactors operate quietly, making them suitable for environments where noise reduction is essential.

Conclusion

Understanding the working principle of a 1.14kV 250A vacuum contactor reveals the intricacies of this essential electrical device. Its unique design, characterized by a vacuum environment, allows for reliable operation, reduced arcing, and compactness, making it a preferred choice in various industrial applications. As technology continues to evolve, vacuum contactors will likely play an even more significant role in the future of electrical engineering, contributing to the efficiency and reliability of electrical systems worldwide.

Haibang, as a leading provider of electrical products, offers high-quality AC vacuum contactors designed to meet the needs of different industries. With Haibang's AC vacuum contactors, power distribution systems can achieve optimal performance, enhanced safety, and improved efficiency. Contact Haibang today to explore their range of AC vacuum contactors and experience the benefits they bring to power distribution applications.

If you are interested in our products ,welcome to contact us.

Email:[email protected]