Welcome to our blog post on the application of silicon core pipe extrusion production line! If you're looking for a cutting-edge technology that revolutionizes the manufacturing of pipes, then you've come to the right place. In this article, Jwell Machinery will delve into what exactly a silicon core pipe extrusion line is and explore its various applications. Whether you are in the construction industry or involved in infrastructure development, understanding this innovative solution can take your projects to new heights. So let's dive in and discover how this advanced production line can make a significant impact on your operations!

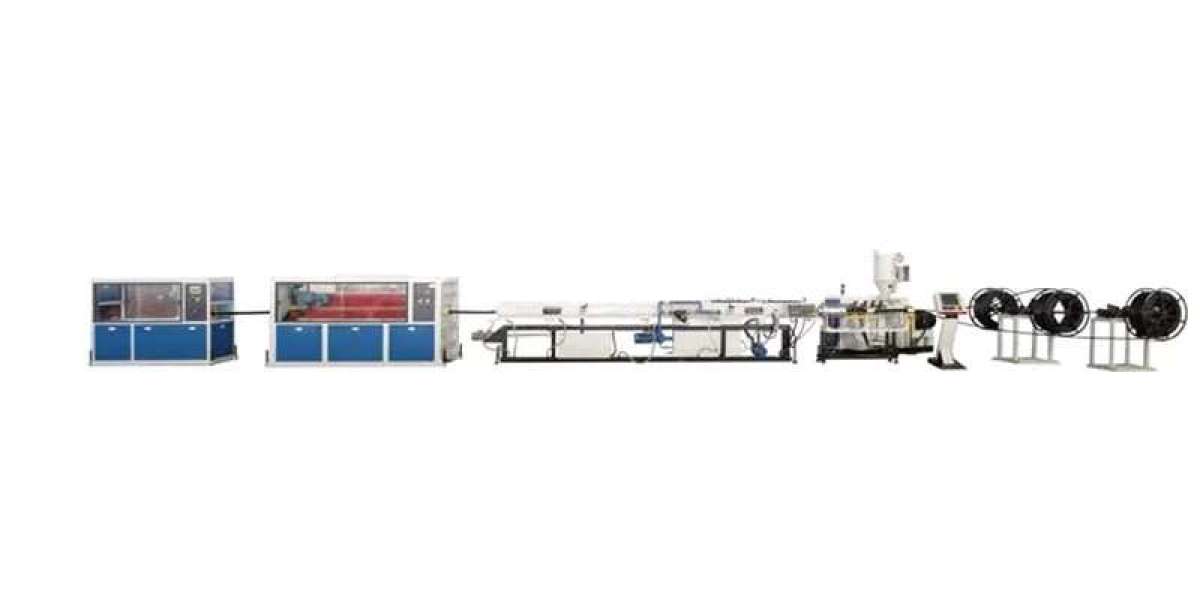

What is silicon core pipe extrusion production line?

Silicon core pipe extrusion line is a cutting-edge technology that revolutionizes the manufacturing process of pipes. It involves the extrusion of a high-quality silicon layer onto traditional plastic pipes, resulting in enhanced durability and performance. This innovative solution combines the flexibility and strength of plastic with the superior insulation properties of silicon.

The process begins with feeding plastic pellets into an extruder, where they are melted and forced through a die to form the desired shape and size of the pipe. During this stage, an additional extruder introduces liquid silicone into the main stream, which adheres to the outer surface of the pipe.

The combination of plastic and silicon creates a unique composite structure that offers several advantages. It provides excellent protection against corrosion and chemical damage, making it ideal for applications in harsh environments such as underground or underwater pipelines. Its superior insulation properties ensure efficient conveyance of fluids while minimizing energy loss.

Moreover, silicon core pipe extrusion production line enables faster installation due to its lightweight nature compared to traditional metal or concrete pipes. The seamless integration between different sections eliminates weak points often found in jointed systems.

This advanced technology opens up new possibilities for industries such as telecommunications, water supply networks, electrical installations, and more. With its exceptional durability and versatility, silicon core pipe extrusion production line is truly revolutionizing modern infrastructure development!

Application of silicon core pipe extrusion production line

The application of silicon core pipe extrusion line is gaining popularity in various industries due to its numerous advantages. One key area where this technology is utilized is in the telecommunication industry. Silicon core pipes are used as protective casings for fiber optic cables, providing a safe and efficient way to transmit data over long distances.

Another significant application of this production line is in the construction sector. The silicon core pipes produced by this process are lightweight yet durable, making them ideal for underground utility installations such as water supply and drainage systems. These pipes offer excellent resistance against corrosion, ensuring longevity and cost-effectiveness.

Additionally, the automotive industry has also started adopting silicon core pipe extrusion production line for manufacturing various components like fuel lines and coolant hoses. The flexibility of these pipes allows for easy installation while maintaining high resistance to temperature fluctuations and chemical exposure.

The application of silicon core pipe extrusion production line extends across multiple industries, offering enhanced performance, durability, and cost-efficiency compared to traditional materials. As technology continues to advance, we can expect further advancements that will revolutionize even more sectors with this innovative production method!

https://www.jwellplas.com/Application-of-silicon-core-pipe-extrusion-production-line.html