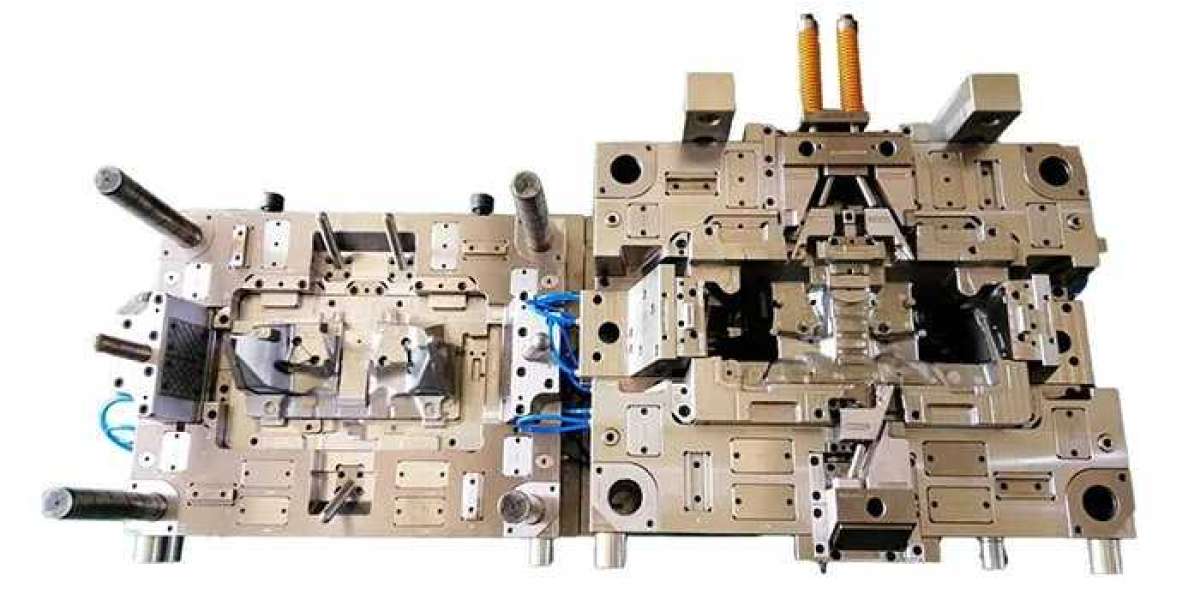

As a motorcycle enthusiast, you know how important it is to have a well-designed and reliable motorcycle. One of the key components that contribute to the performance and durability of a motorcycle is the injection plastic mold. In this blog post, Xuzhong will supply you with the features of motorcycle injection plastic mold and why they are important.

Injection plastic mold is a manufacturing process that involves injecting molten plastic into a mold cavity. The plastic then cools and solidifies, taking the shape of the mold. Injection plastic mold is widely used in the motorcycle industry to produce various parts such as fairings, fenders, and fuel tanks.

Here are some of the features of motorcycle injection plastic mold:

1. High precision

One of the key features of injection plastic mold is its high precision. The mold is designed to produce parts with very tight tolerances, ensuring that the parts fit perfectly and function as intended. This is particularly important in the motorcycle industry, where even small deviations can affect the performance and safety of the motorcycle.

2. Durability

Injection plastic mold is made from high-quality materials that are designed to withstand the high pressures and temperatures involved in the injection molding process. This ensures that the mold can be used repeatedly without losing its shape or integrity. The durability of the mold is important in the motorcycle industry, where parts need to withstand the rigors of daily use and exposure to the elements.

3. Customizability

Injection plastic mold can be customized to produce parts of different shapes, sizes, and colors. This allows motorcycle manufacturers to produce parts that are tailored to the specific needs and preferences of their customers. Customizability is particularly important in the motorcycle industry, where riders often want to personalize their bikes to reflect their individual style and personality.

4. Cost-effectiveness

Injection plastic mold is a cost-effective manufacturing process, especially when producing large quantities of parts. The mold can be used repeatedly to produce identical parts, reducing the cost per part over time. This makes injection plastic mold an attractive option for motorcycle manufacturers who need to produce large quantities of parts at a reasonable cost.

5. Consistency

Injection plastic mold produces parts that are consistent in terms of quality and appearance. This is because the mold is designed to produce identical parts every time, ensuring that the parts meet the same high standards of quality and performance. Consistency is important in the motorcycle industry, where parts need to function reliably and look good over time.

6. Sustainability

Injection plastic mold is a sustainable manufacturing process that produces minimal waste. The plastic used in the process can be recycled, reducing the environmental impact of the manufacturing process. Sustainability is becoming increasingly important in the motorcycle industry, as riders and manufacturers alike seek to reduce their carbon footprint and protect the environment.

In conclusion, injection plastic mold is an important manufacturing process in the motorcycle industry. Its high precision, durability, customizability, cost-effectiveness, consistency, and sustainability make it an attractive option for producing high-quality motorcycle parts. As a motorcycle enthusiast, you can rest assured that the parts on your bike have been produced using the latest and most advanced manufacturing processes, including injection plastic mold.

https://www.xuzhongmold.com/Features-of-motorcycle-injection-plastic-mold.html